While I was out there under the hood, L came out and helped by taking some pictures and calling the landlord for me when I got stuck and/or scared. See, spark plugs are fussy things. If they break off inside, your engine is pretty much toast. So when I heard a crack! from within the socket, I scrambled for backup. Turns out I snapped the top off a plug (several, actually, as the job wore on) but that was not bad. I could still get the plug itself out.

For the uninitiated, sparks plugs generally run along either side of the engine, just above the center line of the huge engine block, and they have wires that run from them to a single hub called the distributor cap. The distributor cap is hooked to other engine bits that I don't know about, so I won't go any farther in that direction. My first car, a Plymouth Valiant, had a slant-6 engine, meaning it had six cylinders and they were set up on a slant, making them easy to work on. My recent truck was a Toyota, four cylinder five-speed, and it had four spark plugs. Arnold has a V-8 engine with an automatic transmission and four-wheel drive, and he has eight spark plugs. (Get it? How many cylinders your engine has equals how many spark plugs you need to buy, no matter what else is going on!) Each plug has a wire that is covered by a little rubber boot to keep out the weather and wet and crap. The first thing I did was take off the boot on the plug closest to me, which would be the one on my right, nearest the front of the vehicle.

You may recall that Arnold is a large-ish truck, a Ford F-150 of a 1995 vintage. His hood is pretty high, about armpit high on me. (I'm 5'8" or thereabouts.) Even with the hood open, it's an awfully long reach to get to any engine parts of interest. So I borrowed a couple saw horses from the landlord, laid a plank across them and made myself a little platform on which to stand for this procedure. Even with my makeshift staging, I still had to climb up onto the chassis and lay across the engine to get to everything. I don't have to tell you that I was good and filthy before I was done.

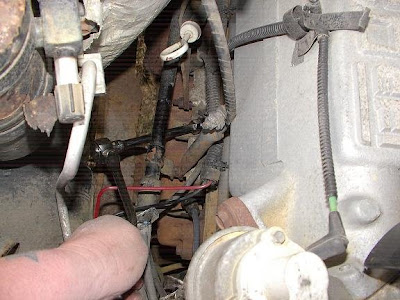

First, here is a picture of me trying to get at the number 7 spark plug, which was the third one back on the right side. It was also the first plug that I broke. This is less than half-way through the operation.

Then here is a picture of me working to loosen the number 8 plug, the farthest back from the front. It apparently is located just behind the accelerator in the cab of the truck.

Now the only way I know how to do this thing is to take one spark plug at a time, remove the plug, replace the wire, follow it to where it goes, and attach it to the distributor cap and then go on to the next plug. This way I don't have a distributor cap with a bunch of little posts and no clear idea which order the plugs are supposed to be in. And it is very important that they are in the correct order, so the mechanics tell me. If they're not, there will be baaaaaddddd engine juju and expensive repair bills. So I do them one at a time.

Now the only way I know how to do this thing is to take one spark plug at a time, remove the plug, replace the wire, follow it to where it goes, and attach it to the distributor cap and then go on to the next plug. This way I don't have a distributor cap with a bunch of little posts and no clear idea which order the plugs are supposed to be in. And it is very important that they are in the correct order, so the mechanics tell me. If they're not, there will be baaaaaddddd engine juju and expensive repair bills. So I do them one at a time.Only this time I am replacing the distributor cap as well, so I have a new cap to plug things into. I positioned the cap so that it was set up as close to the original as possible, and I wrote on it with a marker, indicating where each spark plug wire should be attached. Then I set it on top of the engine while I worked so it would not get turned and have me accidentally cross-hook those damned wires. Here is the distributor cap after the first side was done. Note that there are four wires attached to it, and five naked posts. The four posts remaining around the outside edge will be connected to the spark plugs on the other side of the engine, and the center post will be attached to that mysterious something (ignition, maybe?) that I referred to earlier. Anyway, here is the cap and wires at the half-way point.

And here is a picture of the wires in their little clip thing that keeps them neat and organized. You can barely see the boot on the end of the first spark plug wire (the most left of the four) and on the last one (farthest right - follow the four wires and you'll see them).

And here is a picture of the wires in their little clip thing that keeps them neat and organized. You can barely see the boot on the end of the first spark plug wire (the most left of the four) and on the last one (farthest right - follow the four wires and you'll see them).

Here is the number 7 spark plug after I finally coaxed it from its home. Note how rusted and corroded the metal parts are. Nasty stuff.

The left side of the engine proved to be much more challenging than the first side had been. I don't know if this was because I had to run the wrench with my left hand or what, but it just seemed more difficult. The ends of the number two and four plugs both snapped off inside the socket, scaring me half to death. If one of those babies breaks off inside, well, I've mentioned that it can be bad. It can be very bad. Here is a picture of the wrench on the third spark plug. It was a pain in the neck to get to, and reluctant to come loose.

Here's a better shot with my hand on the wrench.

That dipstick goes to my transmission fluid. I'll check that tomorrow during the oil change.

I finally got the last of the spark plugs out and replaced with shiny new ones. I put gunk on the ends to make them connect well with the wires, I made sure everything was plugged in where it was supposed to be, I connected the center post of the distributor cap to the mysterious whatever it is that it connects to, I removed the old distributor cap and took out the rotor beneath it, replaced it with a new unit and set the new cap into place. The metal clips gave me a hard time, but I managed to convince them to do their jobs, and we got ready for the final exam: would it start? Roar! Arnold sprang to life and purred like a very large, well-fed kitten.

And then the engine started to smoke.

Oh shit.

White wisps of smoke curled up from around the back part of the motor on the driver's side and on the passenger side as well. I panicked and shut it down, only to be reminded by both L and the landlord that I had doused the works with PB Blaster, a spray designed to loosen rusty nuts and bolts. It was just the solvent oil burning off that caused the smoke. Good god, but that stopped my heart.

I started Arnold back up again and let him idle happily for a while. The smoke cleared and did not return. We took a look at the old distributor cap and rotor. Each of the posts where a spark plug wire goes has a corresponding metal plate underneath, and those plates throw a spark to the rotor, which (surprise!) rotates to catch and channel those sparks to the mystery parts of the motor that make everything run. The plates and the receptor part of the rotor were all horribly corroded. No wonder Arnold has been sputtering so. It is as though he was trying to breath through fabric. It sounds easy at first, but eventually it gets to be real work. Take a look at the cap and rotor and the corrosion. You may need to click on the picture to get a close-up view.

Here are the spark plugs in all of their parts and pieces at the end of the job. What a horror show it was to get those out!

And yeah, I got dirty.

But I was very, very happy. And my truck runs like a dream now. I probably tripled my gas mileage with that one thing. No shit. I can hardly wait to change the oil and filter tomorrow!

9 comments:

It was interesting to watch her lay full body across her engine block. The sweatshirt got put on about half way through the t-shirt is even worse and those shorts are headed for a dye job because they will NEVER come clean.

OMG... Is the cylinder = spark plugs thing really that hard for people to figure out? And I was going to mention about the stuff to loosen the spark plugs, but I guess you got that memo already? Also? Your truck is totally taller than my '96 Chevy (um... OUR '96 Chevy). I'm 5'5" and it's... uh... probably about tit level for me. Not that I'd try home auto repair, myself. I could totally already see the "ummm... I think I have a problem" phone call to dad, and dad doing the "OMFG, you what?" shudder.

Who am I kidding? My dad would have a hard time not laughing long enough to respond.

Which totally makes me sound like an auto dumbass, which I'm not. I just have a knack for losing track of which thing goes where and I don't have a lot of what one might describe as "patience".

I think I understood the words "and," "the," and "of." LOL! While car maintenance is something I know I should know (and would like to), it's not in the cards for the immediate future. In fact, by the time I get around to learning it, cars may be flying. ;)

You amaze me.

What Jen said.

I'm in awe. You constantly amaze me with what you can do. I'm pretty much of a "in a dire emergency I can check the oil" kind of girl, absolutely useless for any kind of home repair. I wouldn't recognize a spark plug if I fell over it, let alone know how to change one. Not sure my husband would either, for that matter LOL.

Lovin' the idea of tripling the gas mileage though - that would almost make learning how to change spark plugs myself worth it. Almost.

this was a fascinating post. i know a lot more about spark plugs than i ever did before. and the distributor cap distributes the sparks... well, it does seem obvious now that you've written it out, it's all in the name, isn't it? and wow the suspense! the smoking engine... i was half convinced the whole thing was going to explode as soon as i turned the key after my oil change. glad arnold's feeling kittenish now, i bet he'll love his drink of fresh oil tomorrow too. nessie has been cheerful since hers though she's still waiting for her new air filter. ;)

Oh my goddess: I am in awe. I can drive the car. That's it. Drive it. Oh, and make the car payments. Somebody else does everything else and I, again, make the payments. Awesome job my friend!

oh my gosh! More and more, woman, you make me feel like a totally useless girlie girl. And that's hard to do. I really should learn to at least pump my own gas...to keep up with you. Heck, I should learn to drive. Well, now I know how to do sparkplugs. ;-)

For the uninitiated, sparks plugs generally run along either side of the engine. Each plug has a wire that is covered by a little rubber boot to keep out the weather and wet and crap.

bucket trucks

A really splendid guide about the ins and outs of truck repair. Thanks! This is something that vehicle owners can have much use for, since not everyone goes with the usual car. Especially since there's a lot of quirks and turns that are quite specific to this thing. People should have a good head on the do's and don'ts, and on the parts that they can improve and upgrade.

G Parts Inc.

Post a Comment